Purpose and Scope

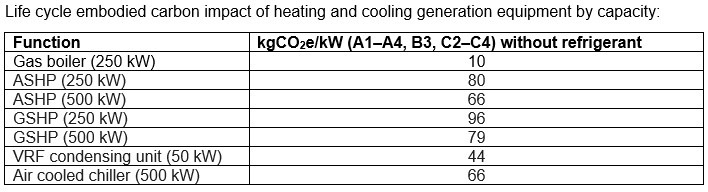

TM65.4 investigates the life cycle embodied carbon impacts of typical UK office HVAC systems. It follows the CIBSE TM65 methodology and RICS whole life carbon standards. The study aims to help engineers make early design decisions (in the absence of EPDs) to minimise carbon emissions from building services.

Study Overview

A typical five-storey, 10,000 m² UK new-build office with current good-practice fabric standards was modelled over:

• a 60-year building life, and

• a 12-year tenancy cycle.

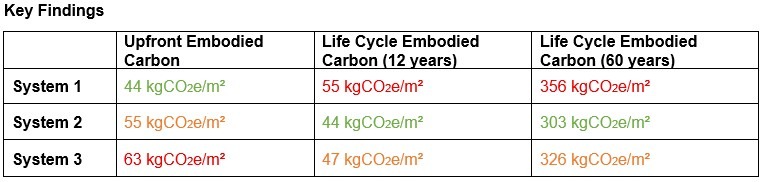

Three common HVAC system configurations were analysed:

• System 1: VRF using R32 + centralised full fresh air ventilation system.

• System 2: ASHP using R32 + FCU + centralised full fresh air ventilation system.

• System 3: ASHP using R32 + passive chilled beams & trench heaters + centralised displacement ventilation system.

Data came from 136 TM65 manufacturer submissions (59 % mid-level and 41 % basic calculations) across 66 manufacturers.

When comparing to the LETI 2030 design upfront embodied carbon target for an office building (350 kgCO2e/m²) (LETI, 2021), HVAC then represents 12–18% of the upfront embodied carbon impact of the whole building.

When compared to the LETI 2030 design target for an office building (750 kgCO2e/m²) (LETI, 2021), HVAC then represents 40–47% of the life cycle embodied carbon impact of the whole building.

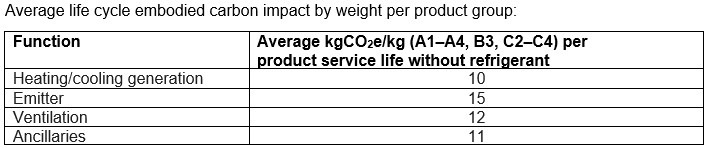

Product Level

System Level

System 1:

• Space conditioning and ventilation (plant, distribution, ancillaries) represent similar embodied carbon impact; refrigerant leakage having the highest single life cycle embodied carbon contribution.

• In addition to the high refrigerant leakage impact, the relatively short service life of a VRF system (15 years as recommended in CIBSE Guide M) requires a high turnover of the heating and cooling generation and distribution resulting in high life cycle emissions when compared to the upfront embodied carbon emissions.

System 2:

• Ventilation (plant, distribution, ancillaries) is the most impactful HVAC equipment in terms of embodied carbon impact. It is driven by the high quantity of ductwork and its frequent replacement at each new tenancy to adapt to a new floor plate layout for the next tenancy.

System 3:

• Cooling emitters represent the largest embodied carbon impact of this HVAC system option. This is due to the chilled beams, which are numerous and have high aluminium content.

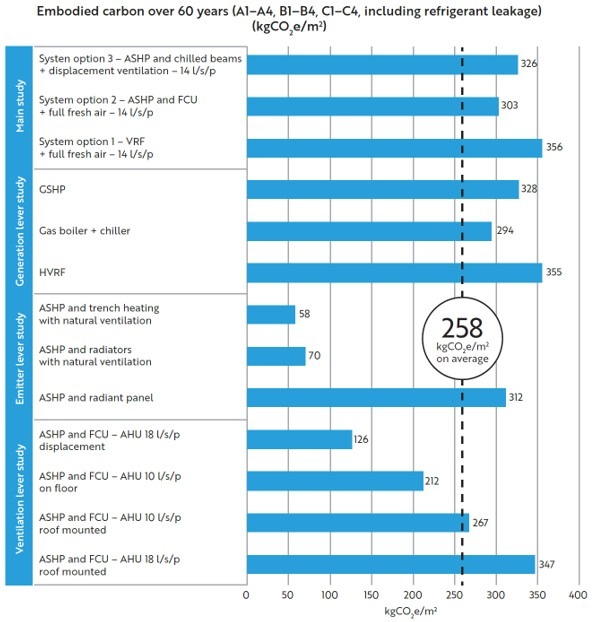

Lever Studies

System 2 was used as the baseline for the level studies. The ventilation study shows that the higher the flow rate, the higher the embodied carbon, with about 14% increase by every 28% increase in ventilation provision (from 10 to 14 then 18 l/s per person). The option of locating AHUs on the floor gives the lowest result due to less centralised ductwork and the required AHUs would be slightly smaller. The split systems (VRF and HVRF) relying on R32 refrigerant show the highest embodied carbon impact due to the impact of refrigerant leakage. HVRF shows a lower impact than VRF as it uses less refrigerant, and therefore less copper piping (replaced partly by PEX pipe). Deciding to remove the cooling function and using natural ventilation significantly reduces the life cycle embodied carbon impact, reducing the impact by a factor of about six.

Conclusions

The life cycle embodied carbon of typical UK office HVAC systems over 60 years is on average 258 kgCO2e/m² (including refrigerant leakage). For comparison, space heating and hot water systems in residential housing is on average 164 kgCO2e/m².

When compared to the LETI 2030 design target for an office building (750 kgCO2e/m²) (LETI, 2021), HVAC then could represent on average 34-36% of the life cycle embodied carbon impact of the whole office building.

This analysis underscores the crucial role of system selection in minimising embodied carbon within HVAC systems. Design strategies like optimising ductwork layouts and using low embodied carbon materials can further improve carbon impact. Additionally, exploring alternative ventilation strategies, such as displacement systems with the raised access floor system in the ASHP with chilled beams option, could offer substantial benefits.

Refrigerant leakage has a significant impact on embodied carbon. It can be reduced by using refrigerant with low global warming potential (GWP), reducing the refrigerant charge by reducing cooling needs, and with good maintenance ensuring there is less to no leakage.

Across all HVAC scenarios that use mechanical ventilation and a centralised full fresh air ventilation system, ventilation is responsible for the highest life cycle embodied carbon impact across 60 years. This is partly due to the large amount of ductwork required and the high embodied carbon of the ventilation products. Alternatives to steel ductwork are available but not widespread. Designers should carefully consider the distribution routing and supply arrangement to minimise ductwork quantities wherever feasible.

The study shows that by going straight to Cat B, instead of starting with Cat A and then Cat B, there is an upfront embodied carbon reduction of an average of 16% across the three scenarios. This saving is largely due to avoiding waste from equipment such as ductwork, piping and related ancillaries.